Benchmarking of Three Integrated Management System Models in Respect to Occupational Health and Safety Management Systems Implementation

Abstract

Organizations use different standardized management systems to run their operations. Management System Standards (MSS), such as Occupational Health and Safety Management Systems (OHSMS), allow organizations to optimize their operation. In order to avoid duplicities, share commonly needed resources, and achieve their strategic goals, companies tend to implement Integrated Management Systems (IMS). Development and implementation of such an IMS have their own challenges and benefits. This study aims to compare three different models to develop and implement IMS by using benchmarking methods. The study is conducted in three steps. First, three holistic IMS models (i.e., ISO 45001, ILO-OSH-2001, and OSHA Recommended Practices) are identified from publications during the past 10 years. Next, three commonly used safety and health standards are identified and analyzed to develop benchmarking criteria. Finally, the three identified IMS are benchmarked. The findings show that each IMS model has its own advantages and shortcomings. The major differences may be due to the way each model is developed. Overall, there are gaps between the models’ concepts and elements and how they are implemented. By understanding the characteristics of each IMS model, management can custom design their own IMS models by modifying the existing IMS models to better fit their organization.

KEY WORDS: Management Systems Standards, Integrated Management System, benchmarking, occupational safety and health

1. Introduction

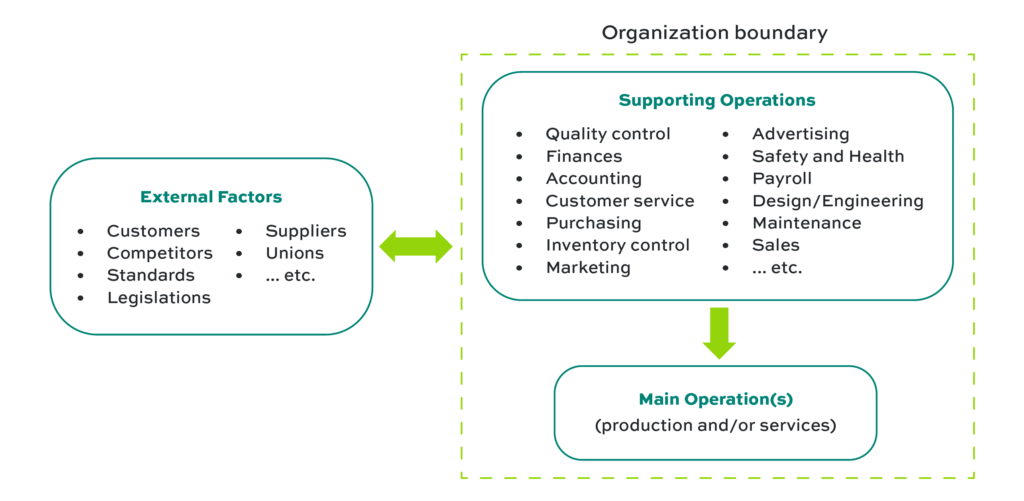

There are different aspects of management that make a company function in a sustainable manner in terms of profitability and finances, quality of products or services, safety and health of employees, etc. Every activity that is performed in a company can be grouped into one of the following two operations: main operation(s) and supporting operation(s). The main operation(s) is a set of activities essential for the company to successfully achieve its objectives and complete its mission. The supporting operation(s) are sets of activities that are necessary to make the main operation(s) efficient (Fig. 1). For example, the main operation(s) can be manufacturing a particular good or providing services to potential customers, and supporting operation(s) can be purchasing, accounting, quality control, inventory control, customer services, payroll, and safety and health systems, to name a few.

Any company, regardless of size and type of product/service, needs to establish specific strategies, procedures, documentation, etc., to align its primary and supporting operations with the company’s objective and mission. Research has shown that such organized efforts can be standardized according to specific models developed by experts to help organizations improve performance and create an organizational culture that engages everyone in a continuous improvement cycle of planning, self-assessment, and correction (Dominques et al., 2016a, Hardjono et al., 1996). Management System Standards (MSS) are the models developed by prominent organizations in standardization, such as International Organization for Standardization (ISO), American National Standard Institute (ANSI), and British Standards (BSI), among others. Some are industry-specific, while others are generic, and their models can apply to any organization (Boiral and Heras-Saizarbitoria, 2015). A management system can be defined as the way by which an organization manages the interrelated parts of its business to achieve its objectives (ISO, n.d.).

It is possible that a company uses more than one MSS to conduct its business. It is management’s responsibility to coordinate all the activities performed simultaneously through each MSS since there are overlaps among them. In other words, there are activities that are required by more than one MSS, or there are resources needed by multiple MSS at the same time. This is when management should try to integrate all MSS that have been developed and implemented independently into one overall and comprehensive system, optimizing its operations and using its resources more effectively. There is no universally accepted definition for Integrated Management System (IMS). The commonly used definitions are, “A single integrated system used by an organization to manage the totality of its processes, in order to meet the organization’s objectives and equitably satisfy the stakeholders,” (CQI-IMSIG, n.d.) or “An integrated management system (IMS) is a management system which combines all components of a business into one coherent system so as to enable the achievement of its purpose and mission,” (Olaru et al., 2014).

Since there is no international standard for IMS, companies must decide how to design and implement an IMS that fits their needs (Bernardo et al., 2009). Despite existing studies, there is no blueprint for developing a factual IMS in a step-by-step manner (Muthusamy et al., 2015). A factual IMS consists of essential MSS, which can be found or used in any industry and environment and provides for the adoption of future MSS and obligatory compliances. It is an IMS that allows organizations to smoothly integrate all MSS that are applicable to the business function, maximize the strengths of these MSS, and be able to update the IMS as new applicable standards evolve. The lack of institutionalization and standardization of IMS has resulted in varied outcomes when IMS is implemented (Domingues et al., 2016; Domingues et al., 2016). Recently, there has been research to develop holistic IMS models to achieve an ideal and tailored IMS suitable for any organization’s business goals.

Among all the different management systems, this study is focused on Occupational Health and Safety Management Systems (OHSMS), whose purpose is to enable companies to keep employees safe, sustain or even improve the health of the environment, comply with regulations and standards, fulfill companies’ social responsibilities, uphold stakeholders’ confidence, allow profitability, etc. It is evident that some of these areas overlap with other aspects of management, and an IMS can be a helpful approach to successfully implement OHSMS. Depending on which IMS model is used, the effectiveness of OHSMS can vary. The objective of this study is to determine the strengths and weaknesses of selected IMS models in effective implementation of OHSMS by using the benchmarking method with minor modifications. This allows the researchers to make comparisons across IMS instead of companies/organizations.

Benchmarking is an ongoing activity of comparing one’s own processes, production, or service (such as occupational health and safety programs) against the best know similar activities. This allows organizations to take a realistic course of action to become and remain the best organization with best practices in a reasonable time. Through this process, companies can discover new ideas for methods and processes and even adopt good features of similar programs in their own organization (Balm, 1992). There are different types of benchmarking. Functional benchmarking is the one that fits this study, and it focuses on a single function or operation for improvement. This is suitable for complex operations such as occupational health and safety, human resources, finance, and accounting, which are difficult to be compared directly in terms of cost and efficiency (Karlöf & Östblom, 1993; Balm, 1992). Instead of making comparisons across companies, it is done across three selected IMS models. Determining the advantages and disadvantages of selected IMS models in regard to OHSMS implementation can help companies select the right model to maximize their productivity and performance.

2. Methodology

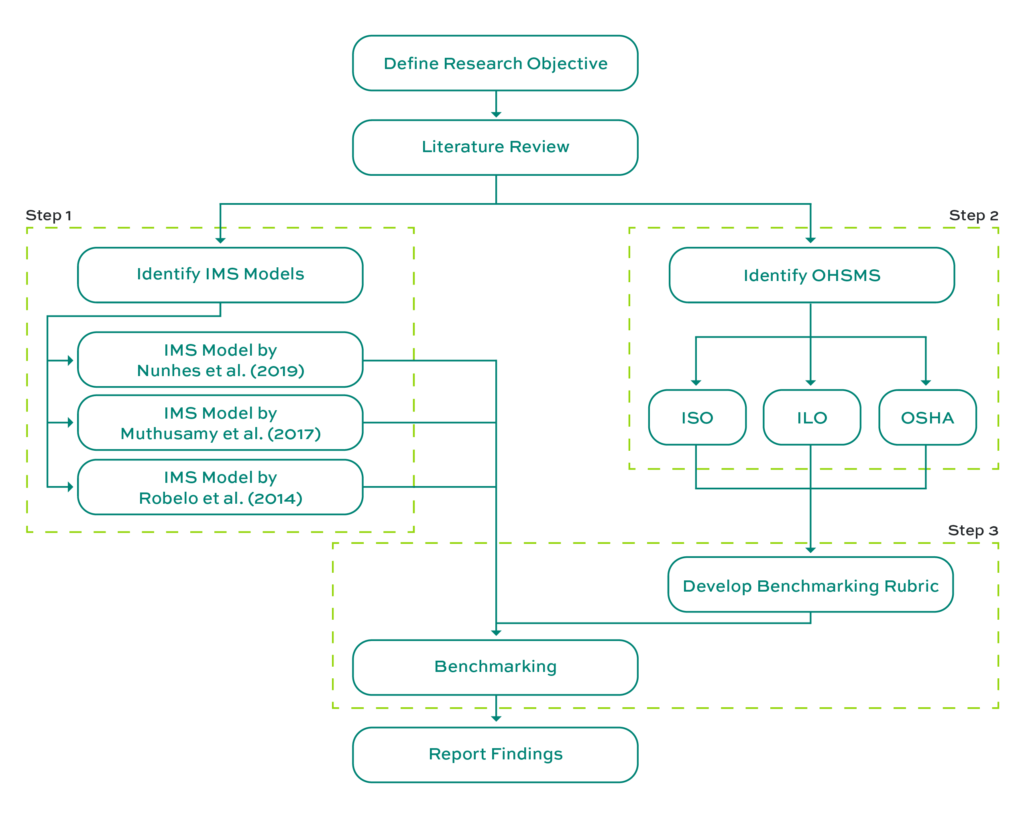

Figure 2 represents the overall approach used for this study, which marks the three steps described in the methodology section. In order to do functional benchmarking across IMS models in regards to OHSMS, a 3-step approach is utilized. First, it is necessary to identify the IMS models recommended and used during the past 10 years. It is essential to select IMS models that are holistic (generic) and have been used by or recommended for various industries and avoid industry-specific models. As explained in more detail in the Results section, the three models selected in this study are the ones published by Nunhes et al. (2019), Muthusamy et al. (2017), and Robelo et al. (2014).

Second, the most commonly used OHSMS across industries are identified. This step is a prerequisite for the next step. The selected OHSMS should be the type of management systems widely accepted by experts, developed by credible organizations, and commonly used in industry; they should not be industry-specific systems.

Third, it is essential to develop benchmarking criteria by which the selected IMS models are assessed. To complete this step, the authors studied the OHSMS selected in step two and identified major elements of each system, and categorized them in different criteria.

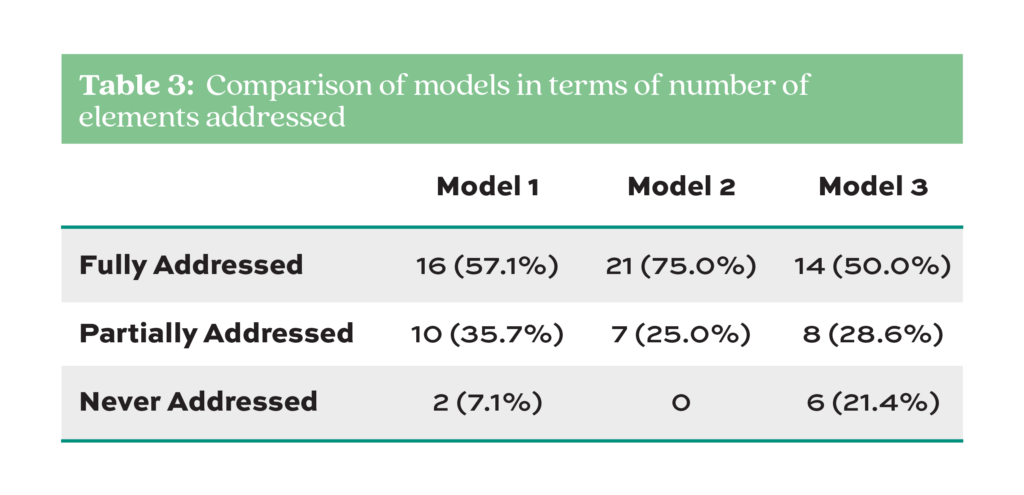

All three steps rely heavily on a literature review of published peer-reviewed journal articles, conference proceedings, and books written during the past 10 years. A scoring scheme is developed based on how each IMS model addresses each element of benchmarking criteria. If the IMS fully addresses the element, a score of 2 is assigned; if it is not addressed, a score of 0 is assigned. In case the element is partially addressed by the IMS model, a score of 1 is assigned. In the end, the overall scores for all criteria of all IMS models are compared to identify the strengths and weaknesses of each model.

3. Results

As is mentioned in the Methodology section, for step 1, the IMS models that are selected in this study are the ones recommended by Nunhes et al. (2019), Muthusamy et al. (2017), and Robelo et al. (2014). Each of these three models intended to create synergy across various MSS by integrating them, while each used a different approach. Nunhes et al. (2019) created guiding principles for IMS through a systematic content analysis of the 30 most cited articles between 2006 and 2016. They identified essential elements for its development and maintenance in order to move towards unifying a starting point in the literature. Muthusamy et al. (2017) developed a comprehensive IMS model for the holistic integration of MSS, which called for a Factual IMS model. While Rebelo et al. (2014) developed a flexible, integrator, and lean model for the integration of MSS that can be adapted and progressively assimilated by other management systems, such as SA 8000/ISO 26000, ISO 31000, and ISO/IEC 27001.

The OHSMS that are identified and included in this study (step 2) are ISO 45001 Occupational Health and Safety Management Systems (Dentch, 2018), ILO-OSH 2001- International Labour Organization Guidelines on Occupational Safety and Health Systems (ILO, 2009), and OSHA Recommended Practices for Safety and Health Programs (OSHA, 2016). The ISO and ILO are internationally recognized agencies whose recommendations and guidelines are widely used in management and labor practices. OSHA is another agency that is the official agency in the U.S. to establish safety and health standards for industries. Even though OSHA is a national agency, its standards, guidelines, and recommendations have been adopted by companies in other countries for many years.

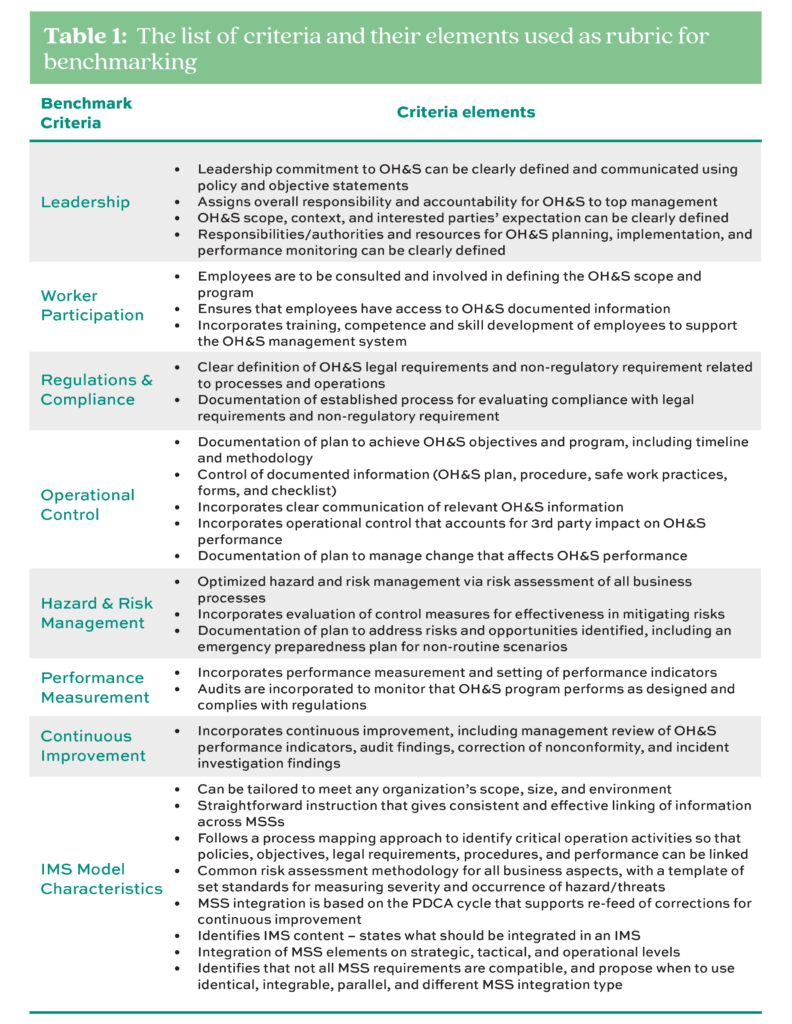

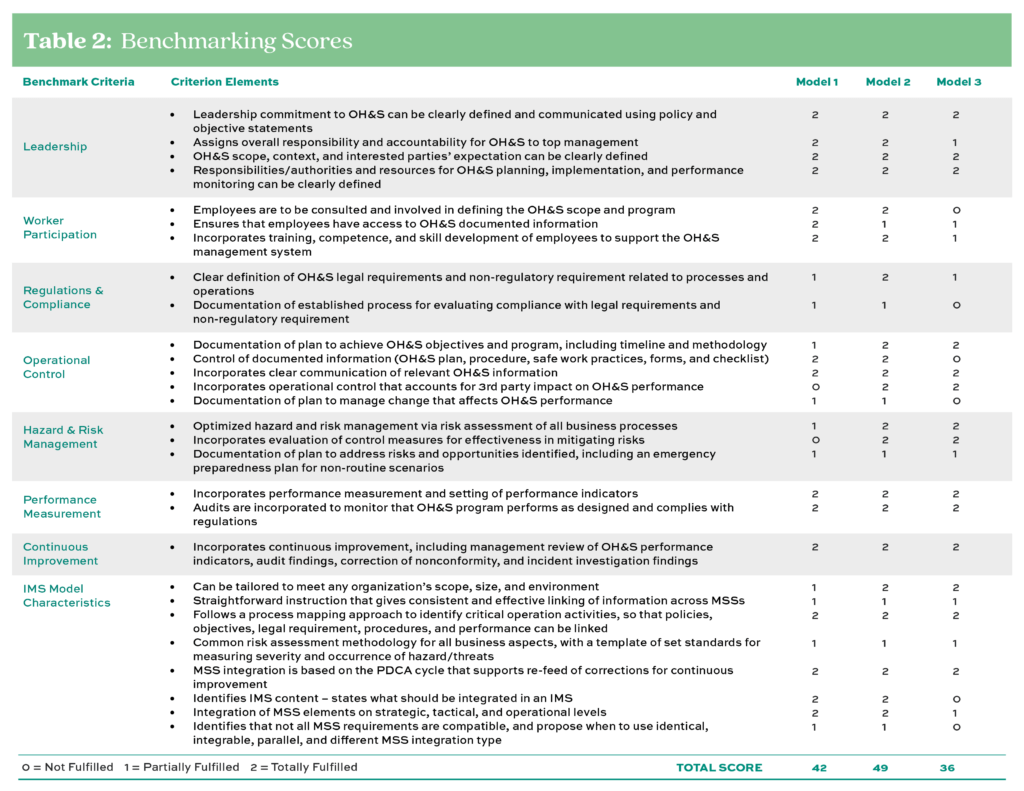

The three selected OHSMS are studied carefully by the authors, and major elements of each system are identified, and they are categorized in eight criteria (step 3). Table 1 provides a list of all the criteria and the elements that are used as rubrics for evaluation and benchmarking of the selected IMS models. As described in the methodology, if an IMS model fully or partially addresses any of the elements in each criterion, a score of 2 or 1 is assigned respectably, and if it is not addressed, a score of 0 is assigned. One of the authors (A.Y.) used the information provided by the published literature to decide if each element under every criterion was fully addressed before assigning a score to them. The number of elements in each criterion is different from one another, and that means the overall scores for each criterion can be different. For example, the highest score for Leadership criterion with 4 elements can be 8, and for Regulation and Compliance criterion with only 2 elements can be 4. Therefore, it is better to normalize the scores by calculating a simple average for each criterion to make the comparison meaningful.

Model 1 (Nunhes et al., 2019) provides 6 systemized principles for implementing IMS, and these principles are based on and made up of 28 elements for the development and implementation of IMS. The elements are cross-referenced with published articles (2006-2016) to determine their frequency of citation, which is used to prioritize the elements. The elements are grouped into principles based on their functionality.

Model 2 (Muthusamy et al., 2017) presents an 8-stage holistic approach for IMS implementation, which is to serve as a process-based strategy for IMS design, implementation, and institutionalization by considering its micro-level perspectives. Also, a comprehensive model of IMS is presented by the authors, which shows how the elements of existing and proposed management systems can be integrated at different levels based on the 4 principal elements of process change put forth by Hardjono et al. (1996).

Model 3 (Robelo et al., 2014) develops a flexible, integrator, and lean model for IMS based on ISO 9001, ISO 14001, and OHSAS 18001. The model is designed such that it can be adapted and progressively assimilate other MSS. It was developed based on a preliminary investigation conducted through a questionnaire. This model consists of 7 fundamental components and provides guiding principles and actions for implementation.

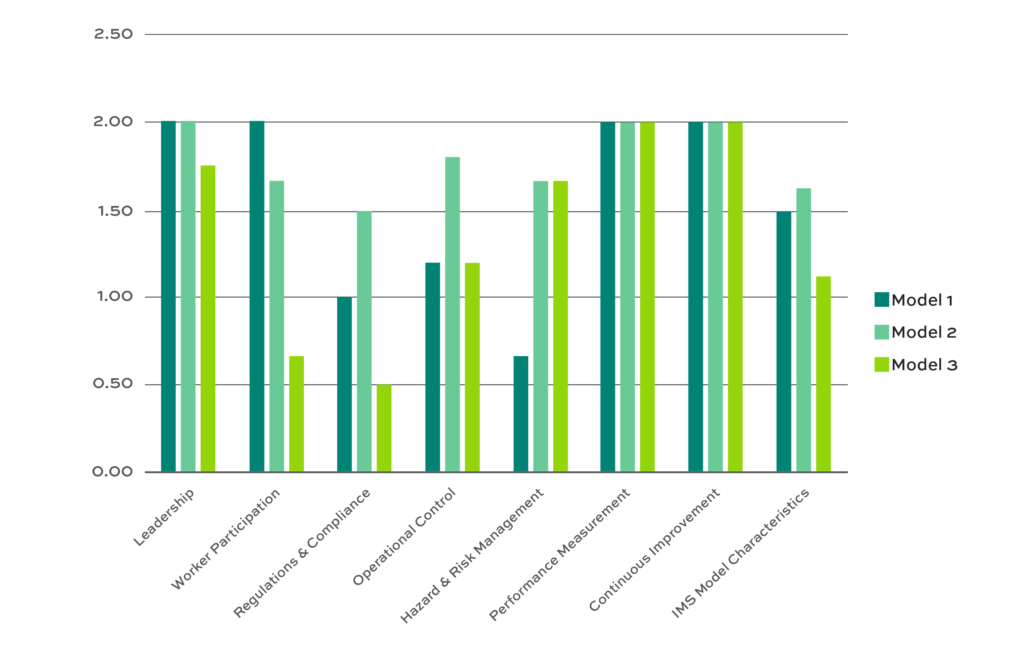

Each of these 3 models has unique characteristics, and depending on which is selected and implemented by any organization, the outcomes of their OHSMS can be different. In order to identify each model’s strengths and weaknesses, the rubric scale, which was developed by the authors (Table 1), is used to benchmark the 3 models described above. Table 2 demonstrates the scores each model receives for each element. Figure 3 demonstrates how each model is scored for each criterion by using the average scores. It seems that the “Worker Participation, Regulation and Compliance, Operational Management, and Hazard and Risk Management” criteria are the four areas where the greatest differences exist.

By counting the number of elements that are entirely, partially, or never addressed by each model, it appears that Model 2 covers more items than the other two (Table 3).

4. Discussion

As discussed earlier, companies are implementing different management systems standardized for specific operations, either main or supporting, to help management and companies achieve their strategic goals. Independent implementation of multiple management system standards (MSS) can lead to a duplication of procedures, primarily with respect to training, audits, and inspections. It can also affect management and operational efficiency by causing complexity and extra cost to the organization (Holdsworth, 2003; Zeng et al., 2007).

With increases in implementing such MSS in a company, the need for integrating such systems increases too. It is very likely that some companies or organizations have already implemented some kind of integrated management system (IMS), or they need to start implementing an IMS for the first time to include occupational safety and health management systems (OHSMS). This process has its own benefits and challenges.

A true IMS should incorporate an essential MSS, along with a sector-specific management system. So far, current integration strategies are unable to adequately provide a complete roadmap for implementation processes of IMS. The lack of clarity and complexity in the integration process puts more emphasis on research to develop better IMS models for companies (Muthusamy et al., 2015). If IMS models allow effective implementation of multiple MSS, it can help organizations cut down on repetition of processes and maximize utilization of resources. A good IMS model should allow companies to tailor the integration process to fit their organizational needs (Bernardo et al., 2009; Lopez-Fresno, 2010).

In this research, the authors use the benchmarking method to assess three different holistic IMS models recommended by others in order to identify their strengths and weaknesses with respect to implementation of OHSMS. The results of this study show that when OHSMS and other MSS are already in place in an organization, management can identify the best IMS model that can optimize the outcomes of the integration process.

The benchmarking criteria are developed based on three commonly used OHSMS, which are accepted by experts in this field (i.e., ISO 45001, ILO-OSH-2001, and OSHA Recommendations). Three IMS models are selected (Nunhes et al., 2019; Rebelo et al., 2014; Muthusamy et al., 2017) and compared against 28 important elements required for an OHSMS to see which one addresses them better.

According to the results of this study, all three models included in benchmarking have certain deficiencies in Worker Participation, Regulation and Compliance, Operational Control, and Hazard & Risk Management areas. In order to explain the differences and deficiencies, it is better to look at each model separately. Nunhes et al. (2019) studied previously published articles about IMS development and implementation and identified major elements cited more frequently. They developed their own guiding principles for implementing an IMS. This model (Model 1) is not concerned about OHSMS or any specific MSS; instead, it tries to address major challenges in the implementation of IMS (i.e., i. lack of resources, ii. dissimilarities among MSS, iii. cultural differences among work groups, and iv. lack of motivation and resistance to change by employees). These could be the reason Model 1 did not score high in Regulation and Compliance, Operational Control, and Hazard/Risk Management criteria in the benchmarking process.

Muthusamy et al. (2018) tried to provide a comprehensive model and holistic approach to allow smooth and efficient integration of different elements of MSS. The researchers developed their model (Model 2) mostly based on the requirements of ISO Standards (i.e., ISO 9000, ISO 14000, ISO 18000, and ISO 26000). Throughout their approach, the authors followed the continuous improvement mentality, and they were focused on the PDCA (Plan-Do-Check-Act) approach. Their holistic approach to the integration process helped their model cover more elements and score higher in the areas in which the first model did not score well. The process used in Model 2 is mostly a top-down process by which the management initiates the integration and manages the process. This could be the reason that this model scored lower in the Worker Participation area in the benchmarking process.

A major difference between Model 3 and the previous two models is that the Robelo et al. (2014) study is empirical. By conducting a survey, they tried to answer four major questions (i.e., i. importance of factors identified as motivators for the implementation of the IMS model, ii. influence of stakeholders on the performance and evaluation of IMS, iii. main internal difficulties in the development of the IMS model and its implementation, iv. potential benefits of implementation of the IMS model). Similar to Model 2, they were strictly focused on ISO standards (ISO 9001, ISO 14001, and ISO 18001), and their goal was to conceive a model which is lean, flexible, and integrator and can be adapted and progressively assimilate other ISO standards such as ISO 26000 (Social Accountability), ISO 31000 (Risk Management), and ISO 27001 (Information Security Management). This model scored low in Worker Participation, Regulation and Compliance, and Operational Control areas in the benchmarking process. The reason for such low scores could be that Robelo et al. (2014) were primarily focused on the practical aspect of the IMS development and implementation instead of the conceptual aspect of it.

5. Conclusion

The three models discussed in this article scored equally or close to one another in other areas (Leadership, Performance Measurement, Continuous Improvement, and IMS Model Characteristics) in the benchmarking process. The major differences remain in the areas which are crucial in the implementation of the IMS model. Considering that Model 3, developed by Robelo et al. (2014), is empirical and data-driven, while the other two models are mostly conceptual and based on literature review. This highlights that there are still gaps between what a comprehensive IMS model should look like and what experts and employees experience when they try to practice their knowledge and implement such models. Knowing the strengths and weaknesses of each IMS model and being aware of the challenges during implementation can help organizations prepare themselves in order to increase the likelihood of success when choosing and implementing an integrated management system. Obviously, there is still room for improvement, and more empirical studies are needed to close the gap between developing IMS models and their implementation.

Funding Details:

This study did not receive any funding from any agency or organization.

Statement of Conflict of Interest:

The authors had no financial interest or benefit from conducting or publishing this study.

References

Balm, G.J. (1992). Benchmarking: A Practitioner’s Guide for Becoming and Staying Best of the Best (2nd ed). QPMA Press.

Bernardo, M., Casadesús, M., Karapetrovic, S. & Heras, I. (2009). How integrated are environmental, quality and other standardized management systems? An empirical study. Journal of Cleaner Production, 17(8), 742-750.

Boiral, O. & Heras-Saizarbitoria, I. (2015). Management System Standards. In Su Mi Dahlgaard-Park (Ed.), The SAGE Encyclopedia of Quality and the Service Economy (390-395). Thousand Oaks: SAGE Publications, Inc.

CQI-IMSIG (n.d.). Chartered Quality Institute-Integrated Management Special Interest Group. https://www.integratedmanagement.info/what-is-ims

Dentch, M. P. (2018). The ISO 45001:2018 implementation handbook: guidance on building an occupational health and safety management system. ASQ Quality Press.

Domingues, J.P.T., Fonseca, L., Sampaio, P. & Arezes, P.M. (2016a). Integrated versus nonintegrated perspectives of auditors concerning the new ISO 9001 revision. IEEE International Conference on Industrial Engineering and Engineering Management, Bali, Indonesia.

Domingues, P., Sampaio, P. & Arezes, P.M. (2016b). Integrated management systems assessment: A maturity model proposal. Journal of Cleaner Production, 124, 164-174.

Hardjono, T. W., Ten Have S., & Ten Have, W. D. (1996). The European Way to Excellence, London: European Quality Publications Ltd.

Holdsworth, R. (2003). Practical applications approach to design, development and implementation of an integrated management system. Journal of Hazardous Materials, 104(1), 193-205.

International Labour Organization (ILO). (2009). Guidelines on occupational safety and health management systems (ILO-OSH 2001) (2nd ed.). Geneva: International Labour Office.

ISO (n.d.). Management system standards, International Organization for Standardization. https://www.iso.org/management-system-standards.html

Karlöf, V. and Östblom, S. (1993). Benchmarking, A signpost to Excellence in Quality and Productivity. John Wiley & Sons.

Lopez-Fresno, P. (2010). Implementation of an integrated management system in an airline: A case study. The TQM Journal, 22(6), 629-647.

Muthusamy, G., Palanisamy, C. & Ammasaiappan, M. (2015). Integrated management systems for better environmental performance and sustainable development – A review. Environmental Engineering and Management Journal, 14(5), 985-1000.

Muthusamy, G., Palanisamy, C., & Mohanraj, M. (2017). A Comprehensive Model and Holistic Approach for Implementing an Integrated Management Systems. Journal of Computational and Theoretical Nanoscience, 15, 392-401.

Nunhes, T.V, Bernardo, M., & Oliveira, O.J. (2019). Guiding principles of integrated management systems: Towards unifying a starting point for researchers and practitioners. Journal of Cleaner Production, 210, 977-993.

Occupational Safety and Health Administration (OSHA). (2016). Recommended Practices for Safety and Health Programs. www.osha.gov/shpguidelines

Olaru, M., Maier, D., Nicoară, D., & Maier, A. (2014). Establishing the basis for Development of an Organization by Adopting the Integrated Management Systems: Comparative study of various models and concepts of integration. Procedia-Social and Behavioral Sciences, 109, 693-697.

Rebelo, M.F., Santos, G., & Silva, R. (2014). Conception of a flexible integrator and lean model for integrated management systems. Total Quality Management & Business Excellence, 25(5-6), 683-701.

Zeng, S.X., Shi, J.J., & Lou, G.X. (2007). A synergetic model for implementing an integrated management system: an empirical study in China. Journal of Cleaner Production, 15(18), 1760-1767.