Applied Ergonomics Risk Assessment

Abstract

Ergonomic risk factors are leading contributors to occupational injuries and illnesses in the form of workplace musculoskeletal disorders (WMSDs) and injuries from human error. Identification, assessment, and treatment of ergonomic risk factors should follow the established risk management process in ANSI/ASSP/ISO 31000 and 31010. While there are numerous ergonomics assessment methods, most are specifically targeted to body segments or specific tasks and applications and require advanced training and knowledge to use proficiently. One method, the Ergonomics Risk Assessment Tool (ERAT), can be applied to most applications by individuals with limited training. In this technical analysis, the authors present a case study demonstrating the multiple risk factors and risk summation theory using the ERAT.

Introduction

Workplace ergonomics can be defined as the applied science of designing workplace demands and environments to accommodate human capabilities and limitations for well-being and optimum performance (Popov, Lyon, Hollcroft, 2022). Such design factors optimize productivity by minimizing operator musculoskeletal stress, fatigue, discomfort, and error potential.

It’s no secret that WMSDs make up 33% of occupational injuries and illnesses resulting in approximately 40% of all workers’ compensation costs (Liberty Mutual) estimated to cost US businesses $20 billion a year (U.S. Department of Labor.) These facts lead to the obvious need for businesses to better identify, assess and manage such risks.

Methodology

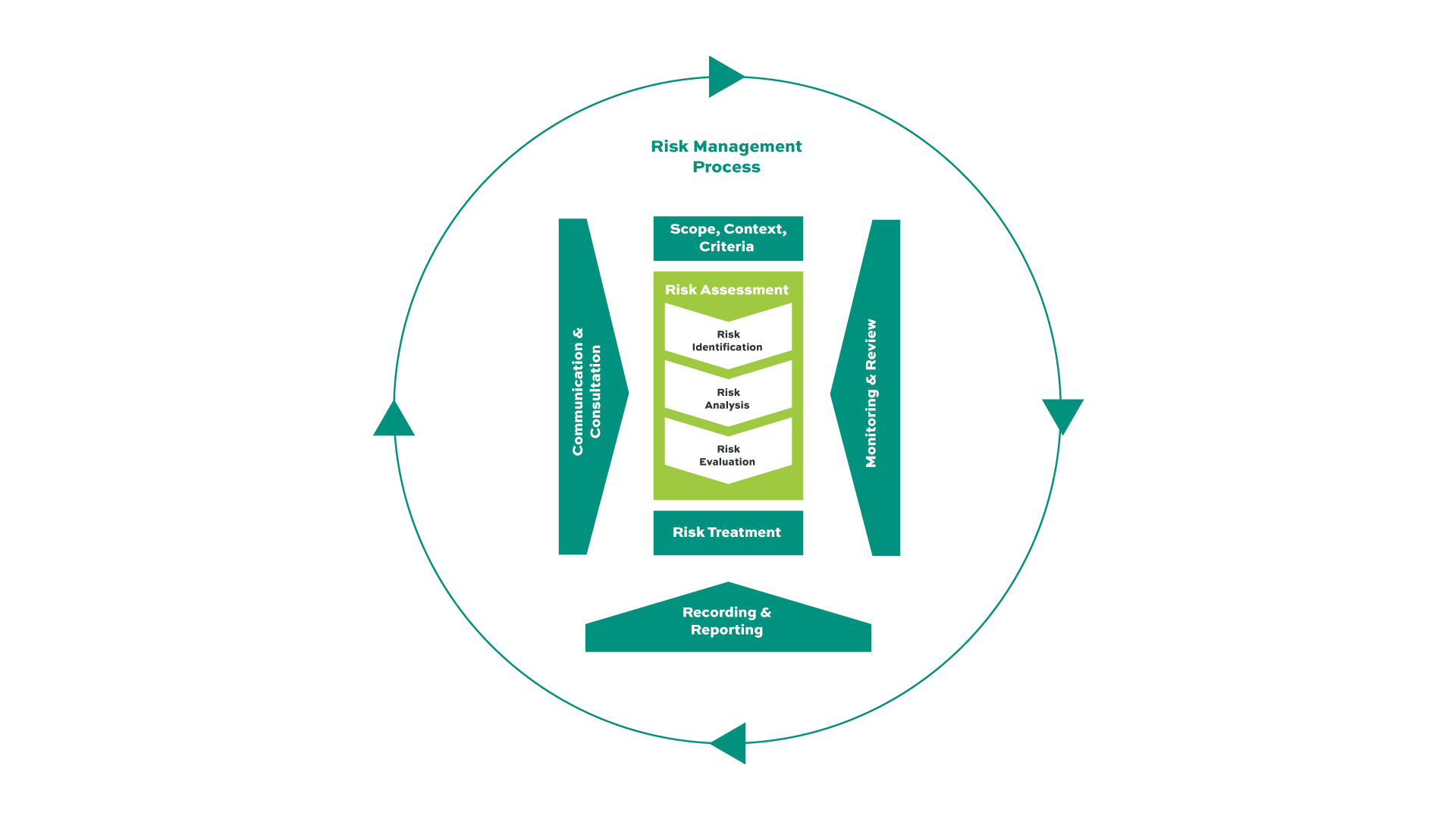

Ergonomic risk factor assessments, like all risk assessments, should follow the methodology established in the ANSI/ASSP/ISO 31000 and 31010 risk management and assessment standards. The risk management process model shown in Fig. 1 is a continuous process.

As with any risk management process, an assessment of ergonomic risk factors should begin with establishing the risk criteria, and context used in the risk assessment. Once established, ergonomic risk factors are identified, analyzed, and evaluated to determine their risk levels and need for treatment and management.

Risk Factors

While considering the scope, context, and criteria, the existing ergonomic risk factors must be recognized or anticipated, identified, and assessed. Ergonomic risk factors are the aspects of a job or task that impose biomechanical stress on the worker. Such factors can have a synergistic effect on the body and contribute to WMSDs. OSHA examines a variety of exposures to ergonomic risk factors in the workplace in their OSHA 3125 publication titled: Ergonomics: The Study of Work (OSHA 2000). In this publication, OSHA included epidemiological studies, laboratory studies, and extensive reviews of the scientific evidence concluding that the following ergonomic risk factors are most likely to cause or contribute to a WMSD:

- Awkward postures

- Cold temperatures

- Contact stress

- Force

- Repetition

- Static postures

- Vibration

- We can probably add hot temperatures, lighting, contrast, and glare

According to OSHA (2000), force (forceful exertions), repetition, and awkward postures, especially when occurring at high levels or in combination, are most often associated with WMSDs. Ergonomic risk factors tend to be synergistic in effect. Individually, an ergonomic risk factor may not contribute a notable risk, however, when two or more risk factors are combined, the risk of biomechanical stress leading to a WMSD can be significantly increased. Tasks or activities that have multiple risk factors have a greater likelihood of causing a WMSD, depending on the duration, frequency, and/or magnitude of exposure to each. Workplace design, activities, and environmental conditions that may contribute to ergonomics-related risk factors include:

- Physical demands of work;

- Work area configurations, layout, and working/walking surfaces;

- Characteristics of object(s), tools, and materials that are handled or used; and

- Environmental conditions such as vibration, lighting, and temperature.

To illustrate how ergonomic risk factors can be assessed, the following case study is presented.

Case Study

Seaweed and algae are natural phenoniums found in most tropical regions because of climate. Unfortunately, as it washes up on beaches, it can create conditions that are unpleasant for tourists. As a result, it is often necessary to remove it manually from tourist-popular beaches as seen in Exhibit 1.

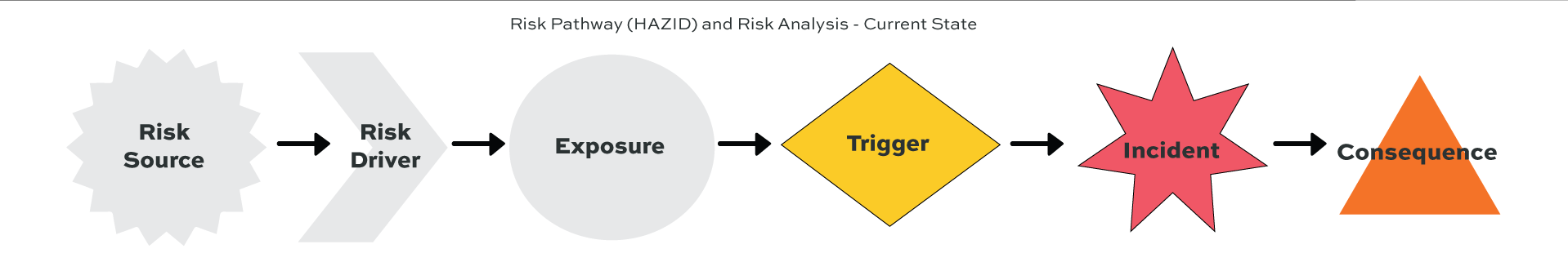

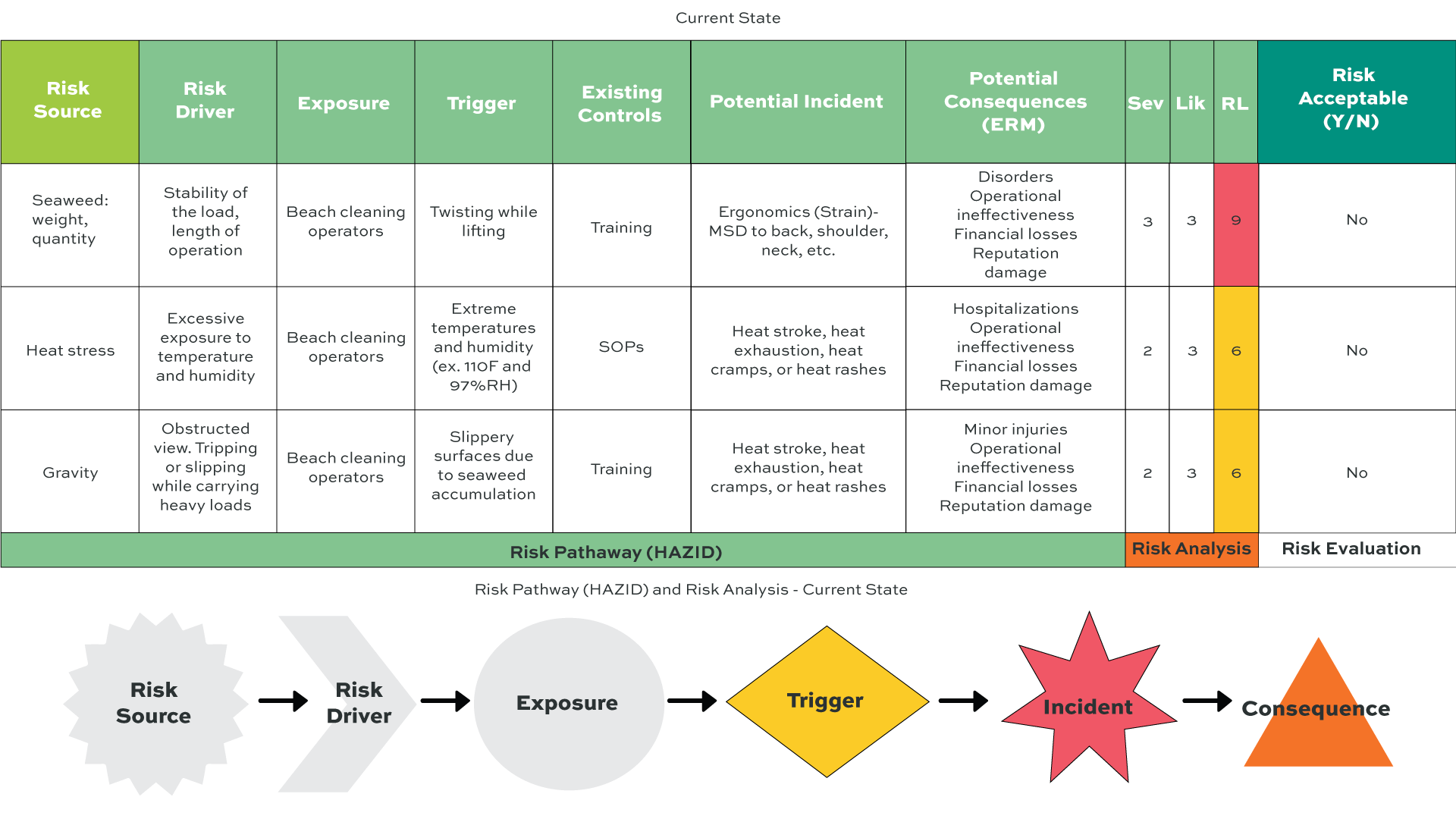

Since no single method can adequately assess the multiple risks associated with this type of task, a combination of methods is used including an ergonomics risk assessment methodology called Ergonomic Risk Assessment Tool or ERAT. Using the risk pathway model shown in Fig. 2, the elements of risk and their relationship can be considered in the risk assessment and treatment process.

Anticipate/Identify Risk

The first step in assessing risk is to identify the risk. This includes anticipating certain risks that could develop or are hidden. This step should describe the risk source, associated risk drivers that may influence the risk source, the exposure at risk, triggers or causes, and any existing controls. There are many identification methods available including the OSHA Ergonomics Assessment checklists, job hazard analysis (JHA), and the NIOSH Lifting Equation – Job Analysis Worksheet. However, there are some limitations to each of these methods. The OSHA Ergonomic Assessment Checklist is primarily designed for manufacturing/industrial operations. JHAs are not typically ergonomics specific or designed to identify ergonomic risk factors. And the NIOSH Lifting Equation is limited to calculating a recommended weight for specified two-handed, symmetrical lifting tasks. (RNLE) However, these hazard identification tools can be used in combination with other ergonomics risk assessment tools.

Risk Analysis and Evaluation

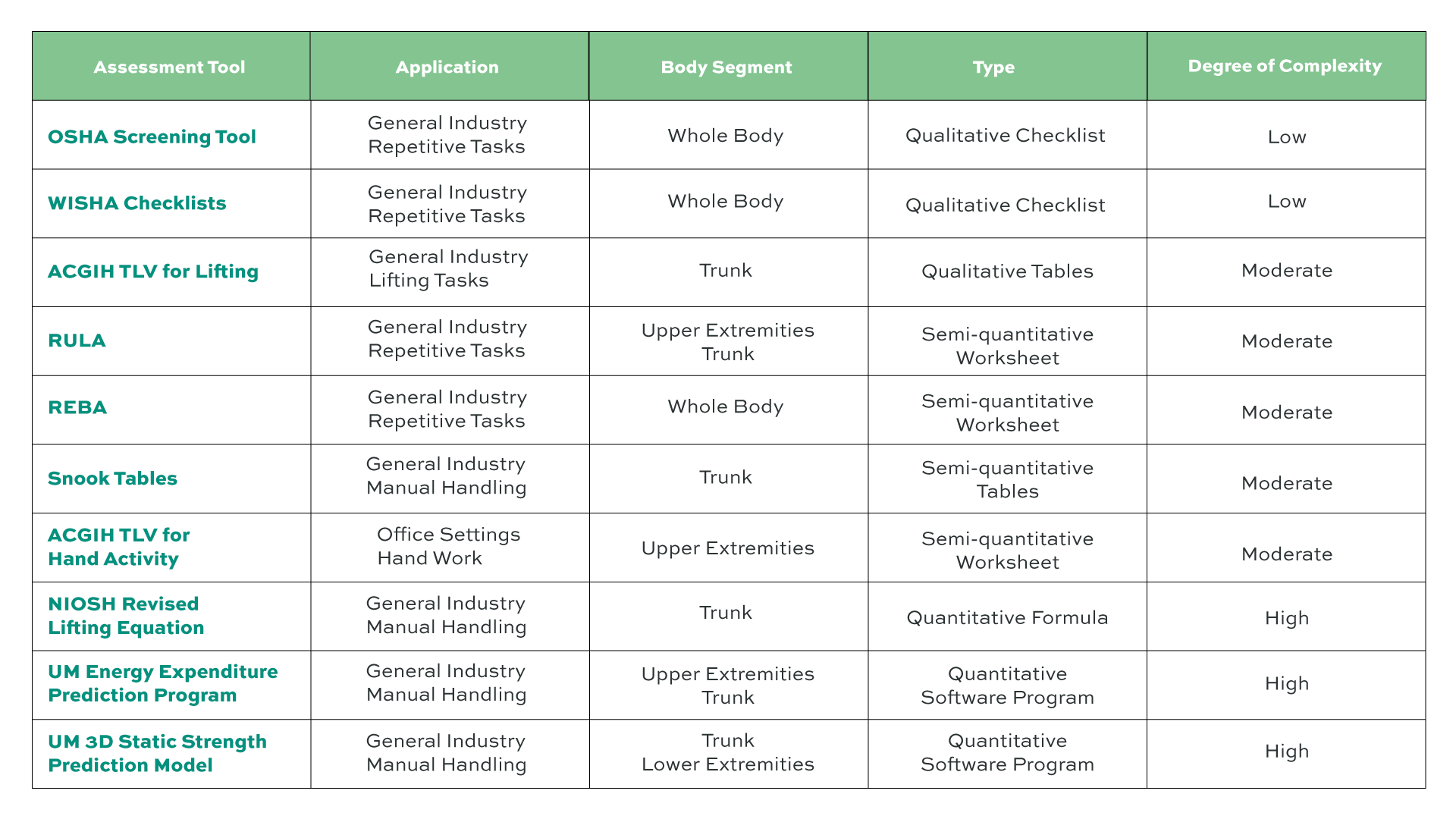

A number of methods can be used to analyze and evaluate ergonomic risk factors. A partial list is provided in Table 1 including their application, body segment, type, and degree of complexity.

Results

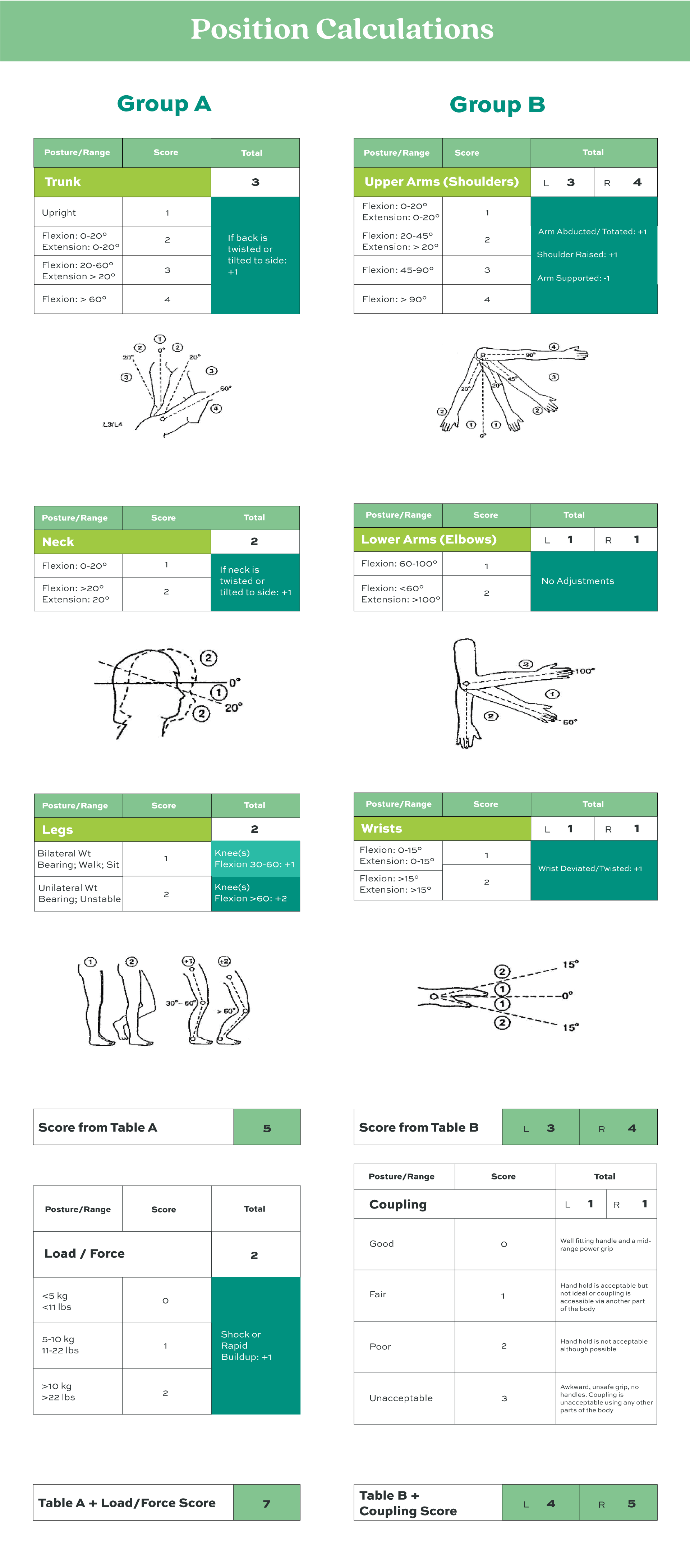

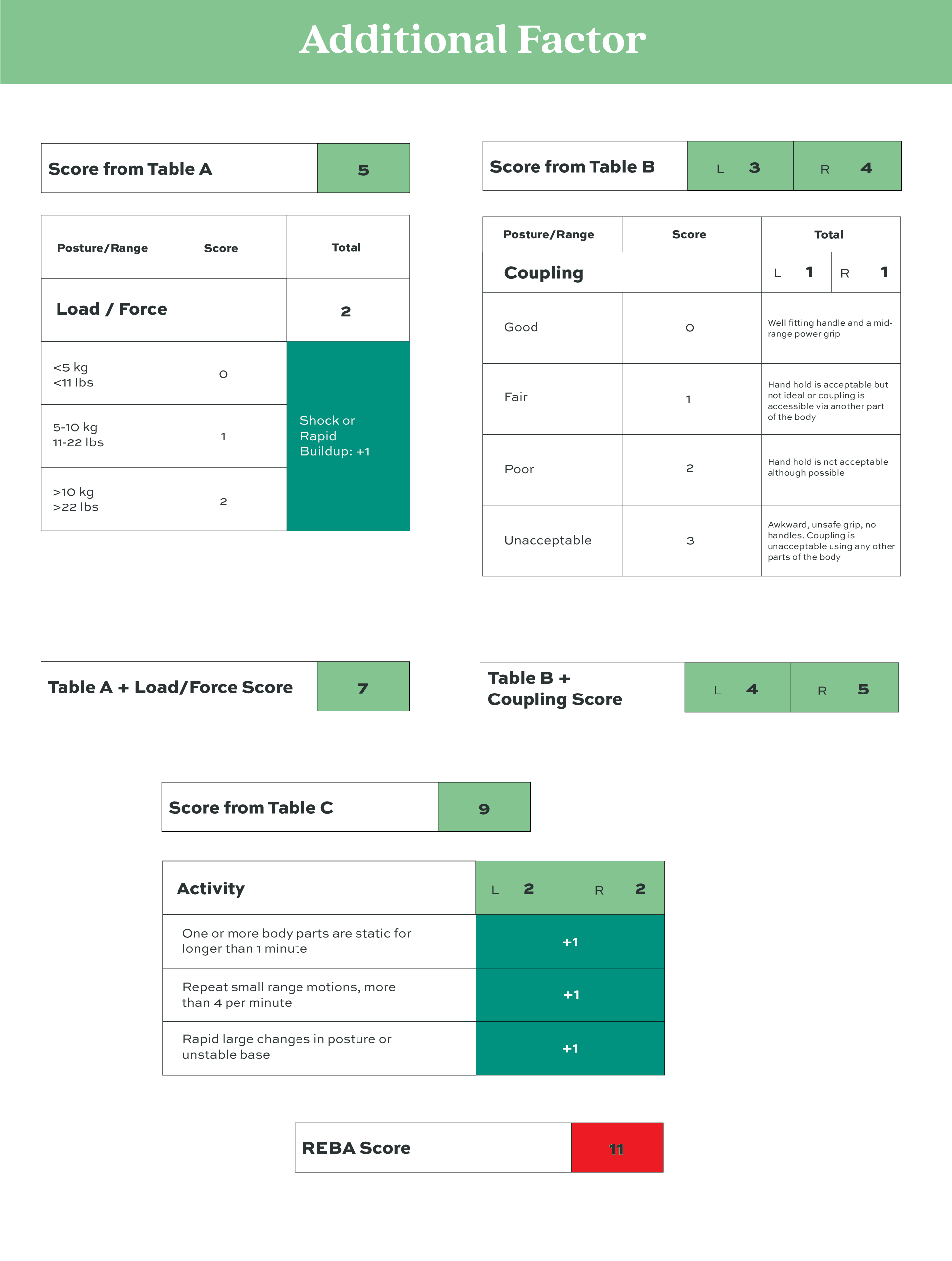

In this case study, the Rapid Entire Body Assessment (REBA) method is selected due to its ability to identify and analyze upper limbs (arm, forearm, and wrist), lower extremities, trunk, and neck postures. For this method, body postures are observed, digitally recorded, and photographed for analysis using either posture diagrams and graphs (pictured in Fig. 3) or software applications. Different types of equipment can be used to measure angles and evaluate the risk in real-time. An example of a REBA semi-quantitative risk assessment is presented in Figs. 3, 4, and 5.

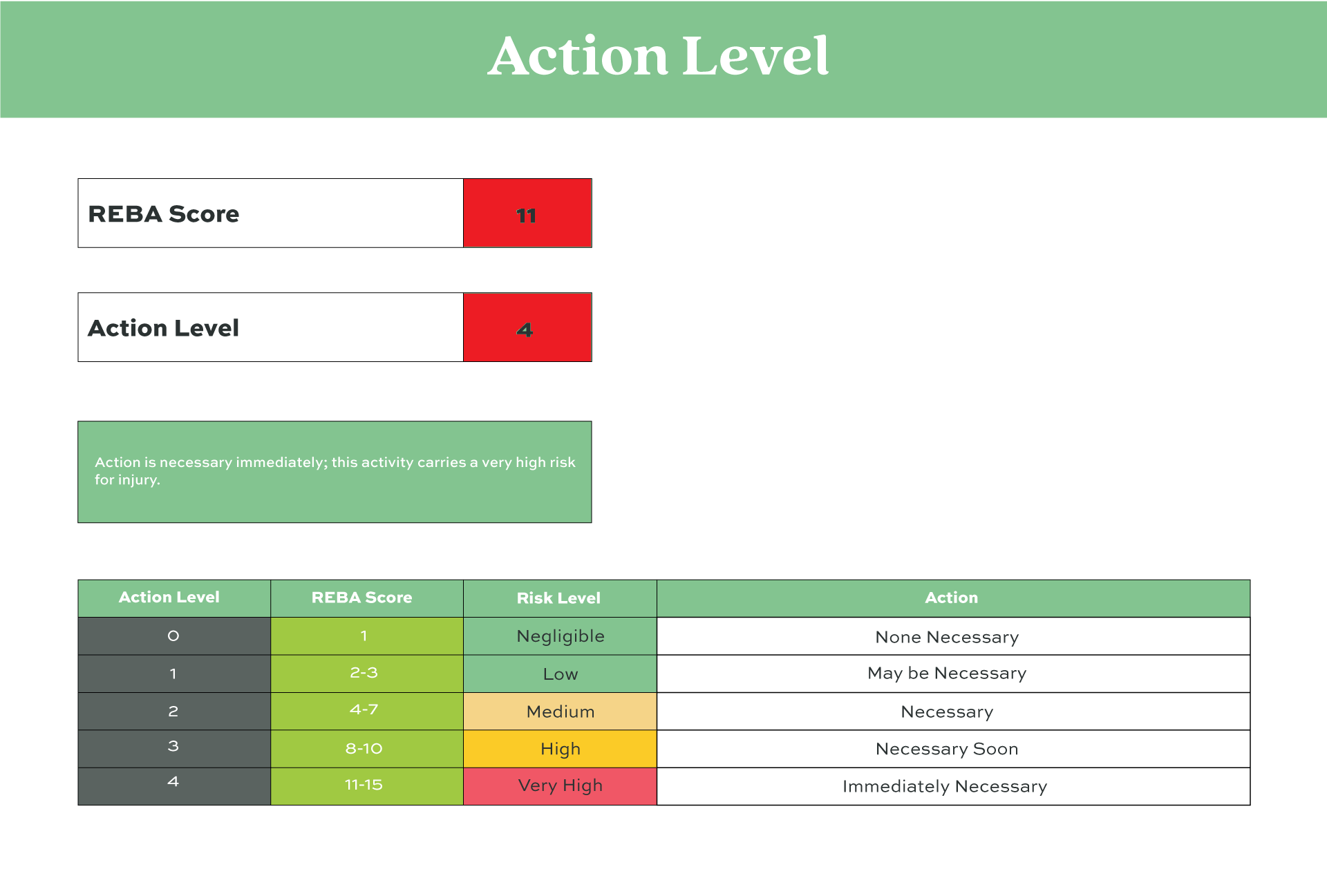

The last step of the ergonomics risk assessment process is risk evaluation. REBA is an important assessment tool since it provides an estimation or risk acceptability referred to as REBA Action Levels. In this case study, the REBA score of 11 is considered a very high risk, shown in Fig. 5.

The assessment method selected should include an assessment of all existing risk factors such as forceful exertions, repetition, duration, static or awkward postures, excessive reach, contact stress, vibration, poor lighting, unstable/slippery surfaces, cold/hot temperatures, humidity, and other factors. Most methods do not include lifting/lowering in an unfavorable environment such as extreme temperature and/or relative humidity. In fact, the revised NIOSH lifting equation does not include factors to account for unpredicted conditions, such as unexpectedly heavy loads, slips, or falls. Moreover, if the environment is unfavorable (e.g., temperatures or humidity significantly outside the range of 19° to 26°C [66° to 79°F] or 35% to 50%, respectively), independent metabolic assessments would be needed to gauge the effects of these variables on heart rate and energy consumption. (NIOSH LE https://www.cdc.gov/niosh/docs/94-110/default.html)

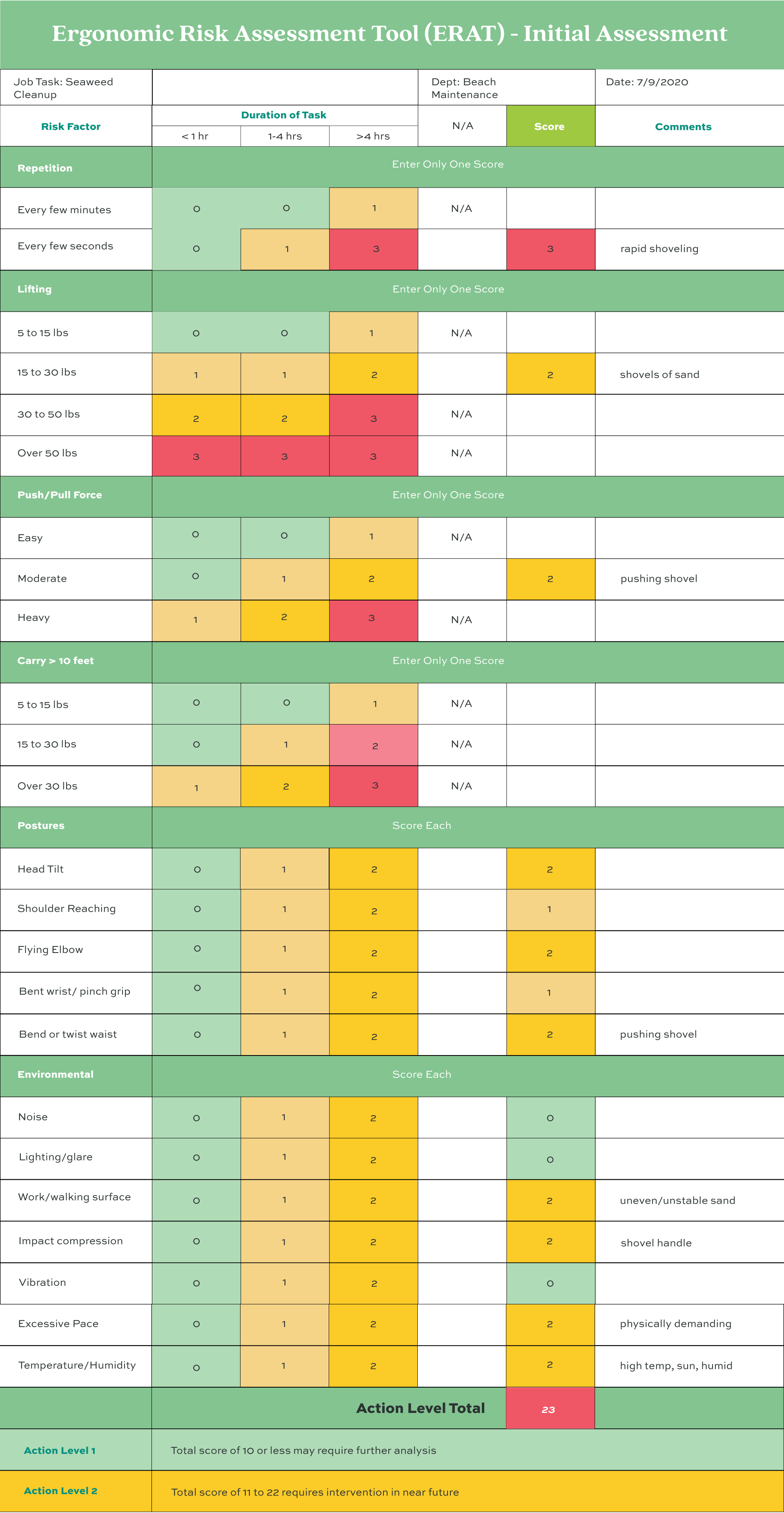

As previously mentioned, OSHAs JHA is not ergonomics specific and OSHA’s Ergonomic Assessment Checklist does not include unfavorable conditions, unusual positions, heat stress, glare, and noise. Considering the limitations of these methods, a more encompassing tool such as ERAT can be used to assess and reduce specific ergonomic risk factors. ERAT was developed from the ergonomics checklist that was part of a working draft document by the Management of Work-Related Musculoskeletal Disorders Accredited Standards Committee (withdrawn in 2003) and can be used to assess ergonomic risks to upper extremities in most work environments including industrial, construction and agricultural settings. (Lyon, Popov, Hanes 2013; NSC 2002).

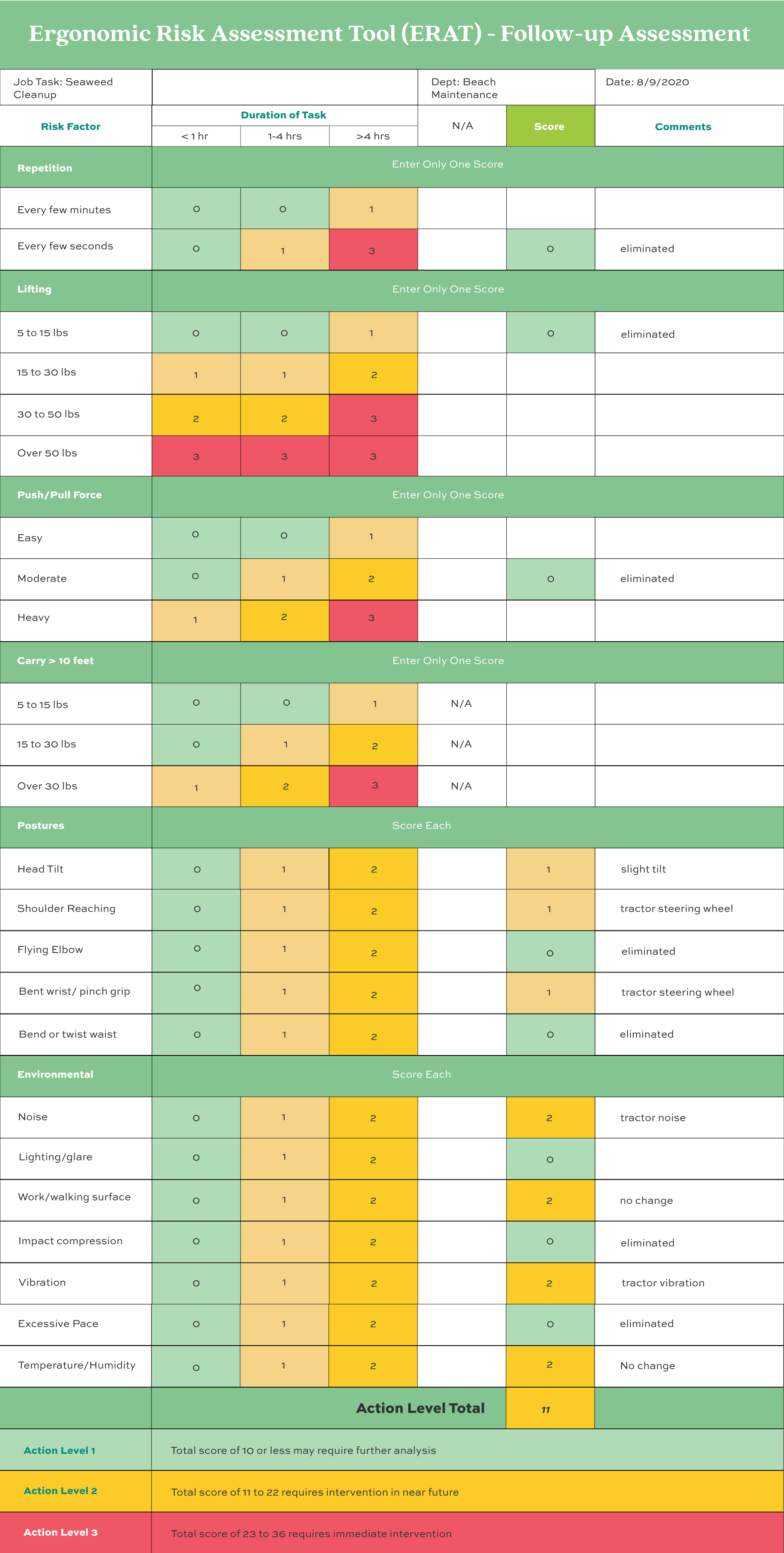

As demonstrated in Fig. 6 the initial assessment using ERAT finds the risk level to be 23 and an Action Level (AL) of 3, which requires immediate intervention.

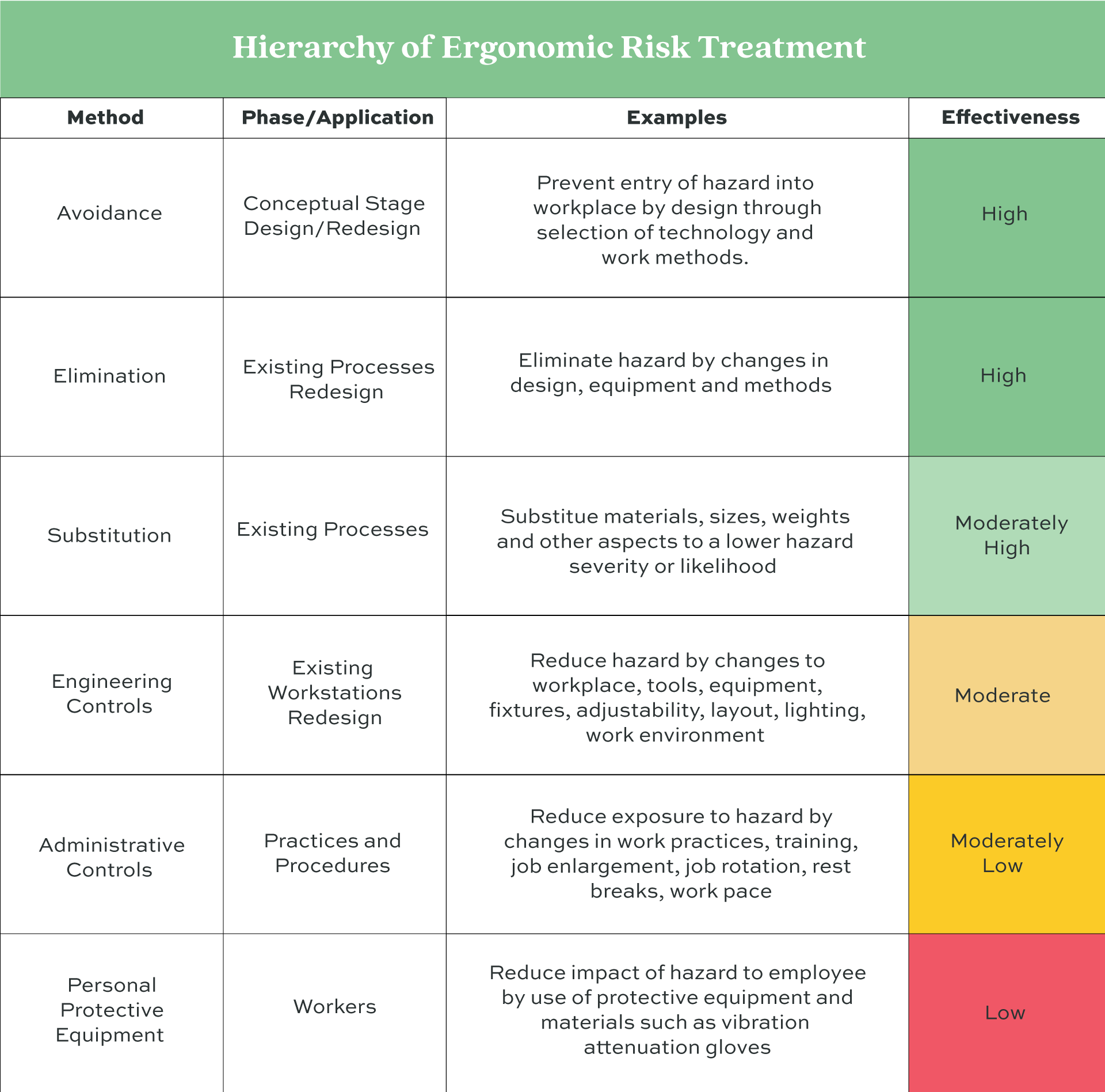

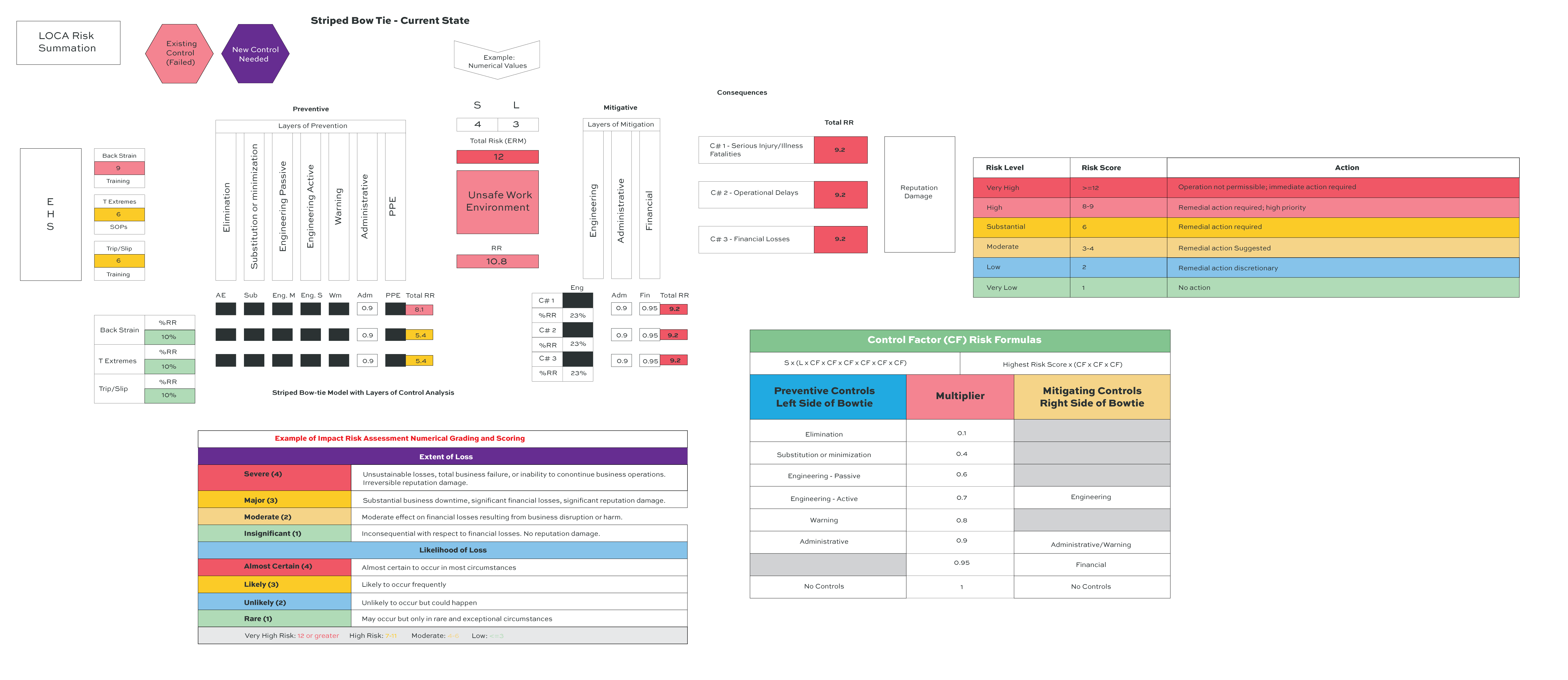

Next, the assessor may suggest temporary improvements using the hierarchy of ergonomic risk treatments. For instance, mechanization using an open cab “seaweed tractor” may reduce some risk factors for WMSD and slips/falls. However, temperature extremes and high humidity risks are still present. The Hierarchy of Ergonomic Risk Treatment is shown in Fig. 7.

Using mechanization to remove seaweed will drastically reduce manual repetitive shoveling of sand and seaweed. However, it does introduce noise and vibration to the operator, as well as wrist and shoulder postures operating the steering wheel. The risk level is reduced to 11 which is an Action level (AL) of 2 as shown in Fig. 8.

Further interventions that include higher level treatments should be investigated to reduce the risk level to an Action Level of 1.

Discussion

Overall, the ERAT is relatively easy to use and includes the assessment of repetition, lifting, push/pull force, carrying, postures, and environmental ergonomic risk factors. This technical analysis demonstrates the importance of including environmental conditions in the ergonomic risk assessment. In addition, an important concept in ergonomic risk assessment is understanding the additive or synergistic effects of multiple risk sources. Ergonomic risk assessment should consider whole system risk and risk summation. In fact, this technical analysis is a good example of how three well-recognized risks can result in greater additive risk. The authors would encourage readers to review BCSPs CSP Blueprint, where the risk summation technique is listed under Domain 2. The risk summation technique is presented in Figs. 9 and 10.

Excess nitrogen and phosphorus increase algae blooms. The root causes (reduction of phosphorus allowed to be discharged directly into water sources, eventually ending in the ocean) should be investigated. However, it will take years to address these issues.

Therefore, many companies are developing innovative solutions implementing higher levels of risk treatment. For instance, an innovative anchoring and turbidity curtain could be considered a solution that significantly reduces the amount of seaweed reaching the beach. An example is shown in Exhibit 2.

Conclusion

OSH professionals are often reluctant to perform ergonomic risk assessments. However, ergonomic risk factors contribute to one third of the incidents and nearly 40% of the costs. OSH professionals have an opportunity to help decision makers reduce these risks and associated costs by assessing and treating specific ergonomic risk factors using higher level treatments. OSH professionals should identify and assess all existing ergonomics risk factors to consider and reduce whole system risk.

References

2021 Workplace Safety Index: the top 10 causes of disabling injuries. (2021, July 15). Liberty Mutual Business Insurance. https://business.libertymutual.com/insights/2021-workplace-safety-index-the-top-10-causes-of-disabling-injuries/

Applications Manual for the Revised NIOSH Lifting Equation (94–110) | NIOSH | CDC. (2021). Centers for Disease Control and Prevention. https://www.cdc.gov/niosh/docs/94-110/default.html

ANSI/ASSP/ISO 31000-2018 (2018). Risk Management. Park Ridge, IL: American Society of Safety Professionals.

ASSP TR-31010-2020 Risk Management – Techniques for Safety Practitioners. Park Ridge, IL: ASSP.

Anchoring and turbidity curtain. Retrieved December 23, 2021, from https://www.erosionpollution.com/support-files/Sargassum-Boom.pdf

ASSP TR-31010-2020 Technical Report: Risk Management – Techniques for Safety Practitioners. (2020). Distributed through American Society of Safety Professionals.

BCSP CSP Examination Blueprint (BCSP CSP). Accessed on December 21, 2021, at

https://www.bcsp.org/Portals/0/Assets/DocumentLibrary/CSP-Blueprint.pdf

BLS (2014). Nonfatal occupational injuries and illnesses requiring days away from work. Bureau of Labor Statistics, US Department of Labor, Washington, DC, USDL 15- 2205: released 19 November 2015. https://www.bls.gov/news.release/archives/osh2_11192015.pdf

CSP Examination Blueprint. (2019). Board of Certified Safety Professionals. https://www.bcsp.org/Portals/0/Assets/DocumentLibrary/CSP-Blueprint.pdf

Erosion Pollution | Erosion Control and Pollution Solutions. (2021). Erosion Pollution. https://www.erosionpollution.com/

Hignett S, McAtamney L. Rapid Entire Body Assessment (REBA). Appl Ergon 2000; 31: 201-205.

Hignett, S., & McAtamney, L. (2000). Rapid entire body assessment (REBA). National Library of Medicine. https://pubmed.ncbi.nlm.nih.gov/10711982/

International Organization for Standardization. (2018). ISO 31000:2018, Second Edition: Risk management – Guidelines: 8.2. Multiple. Distributed through American National Standards Institute (ANSI).

Liberty Mutual Insurance (2020). 2020 Liberty Mutual Workplace Safety Index. Berkeley Street, MA: Liberty Mutual Insurance Company https://viewpoint.libertymutualgroup.com/

article/2020- workplace- safety- index- the- top- 10- causes- of- disabling- injuries/.

Lyons, B., Popov, G., & Hanes, K. (2014). Improving Ergo IQ: A Practical Risk Assessment Model. American Society of Safety Professionals: Professional Safety. https://aeasseincludes.assp.org/professionalsafety/pastissues/058/12/F1Lyon_1213.pdf

Lyon, B.K., Popov, G., and Hanes, K. (2013). Improving Ergo IQ: a practical risk assessment model. Professional Safety (December 2013).

NIOSH Lifting Equation (RNLE) Applications Manual (2021). Revised and Released September 2021. Accessed on December 21, 2021, at https://www.cdc.gov/niosh/docs/94-110/default.html

Nonfatal Occupational Injuries and Illnesses Requiring Days Away From Work, 2014. (2014). Bureau Of Labor Statistics U.S. Department of Labor. https://www.bls.gov/news.release/archives/osh2_11192015.pdf

NSC. (2002). Management of work-related musculoskeletal disorders. (ANSI ASC Z365 Working Draft). Retrieved from www.humanics-es.com/z365_finldrft.pdf

OSHA (2000). Ergonomics: The Study of Work. OSHA 3125. Washington, DC: Department of Labor, OSHA. Accessed on December 21, 2021, at: https://www.oshatrain.org/courses/pdf/OSHAErgonomics.pdf

Popov, G., Lyon, B.K. & Hollcroft, B. (2022). Risk assessment: A practical guide to assessing operational risks. Hoboken, NJ: John Wiley & Sons.